Information exchange platform (IEP) - FAQ

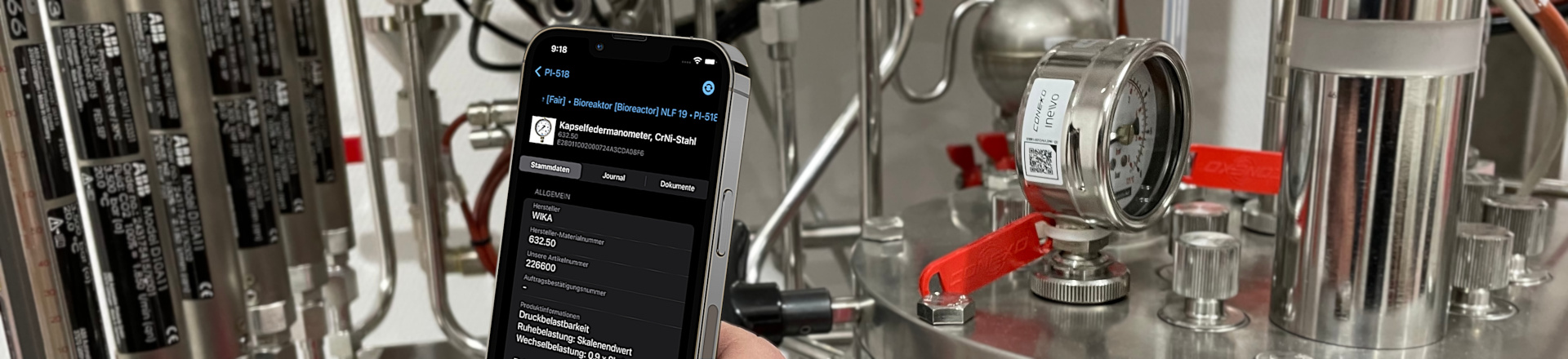

Can the IEP be used to document changes of a physical object in the life cycle?

Yes, this should be possible with an IEP.

Can manufacturers send information updates during the life cycle of a physical object ?

Yes, this should be possible via an IEP. Either via an update of the model information as a supplement to the original documentation. Or directly to the equipment, if this is supported by the IEP and the agreements between operator and manufacturer.

Is information that is generated by the operator during the life cycle visible for the manufacturer?

This should be configured on the IEP in a way that this is only possible upon request, but by default it is visibile only to the operator. If a physical object is send to the manufacturer, relevant information should released to manufacturer via IEP.

For which equipment classes can information be found on the IEP?

In general, for all physical objects. It is particularly worthwhile for objects that are repaired or modified. Where, the IEP represents a life cycle record of the physical object.

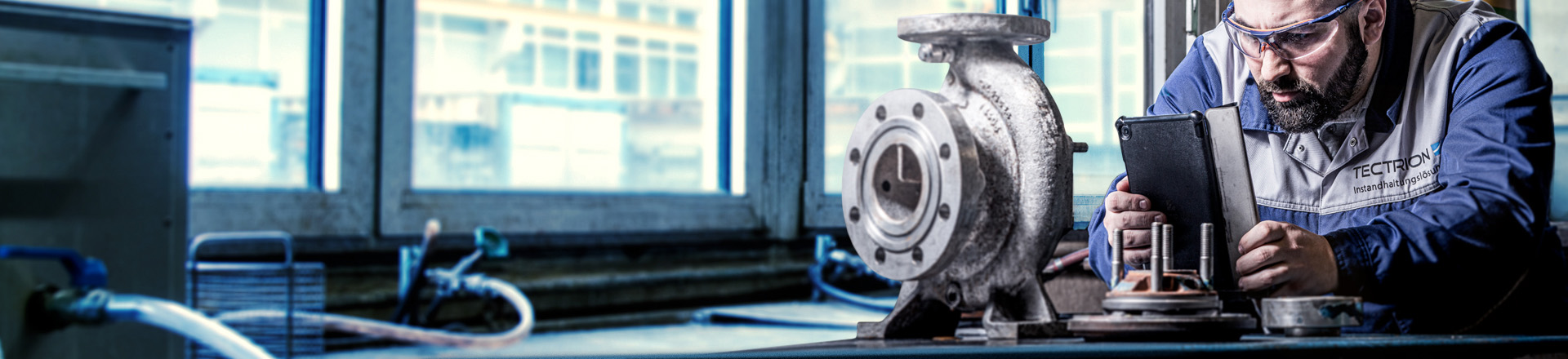

Can operators create equipment information on the IEP?

Yes, this is possible. Especially for old equipments or when the manufacturer does not provide any information.

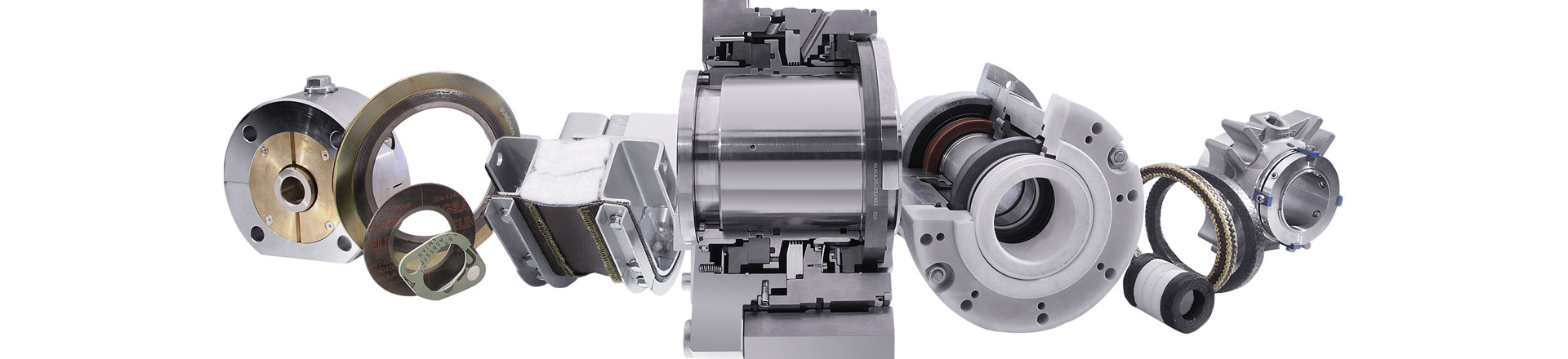

Is it possible to add spare parts information to a physical object on the IEP?

Yes, this is possible. Either in the form of a document or as separate objects, which in turn are stored on the IEP with information.

How can my company add information about physical objects to the IEP?

This is possible manually, by mass upload or via a system interface. It makes sense to check in advance whether the product structure fits and general product information is stored in a bundle. The information on a physical object can then refer to this general product information and be supplemented by specific information of the physical object. The DIN Spec ID is essential information of the physical object and the documentation must meet the requirements of VDI 2770.

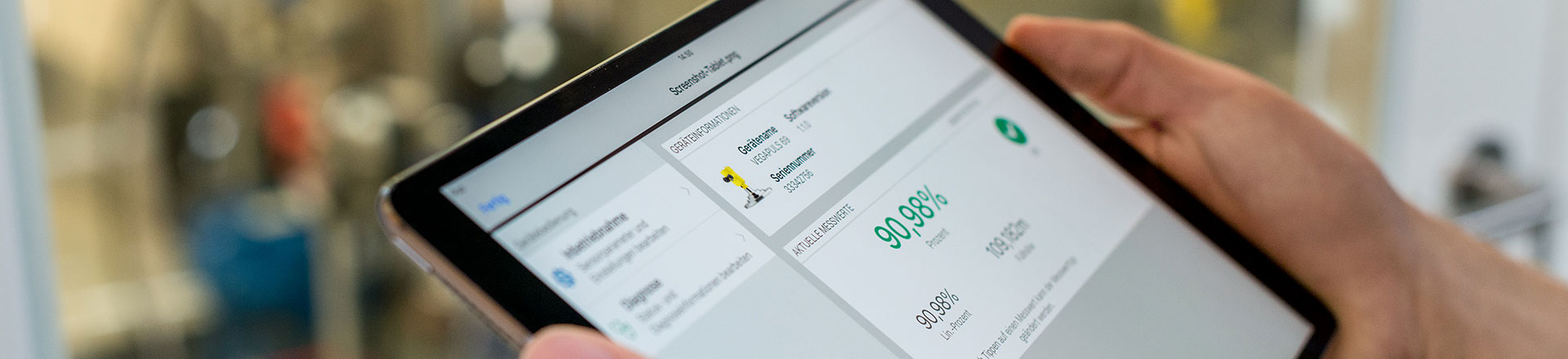

What is the advantage of an IEP over a document management system (DMS) or network storage?

On an IEP, the physical object exists as its own digital object. This enables some functionalities that are difficult to implement on a conventional DMS: 1) Individual documents can be assigned to multiple physical objects. 2) There is an overview page of the equipment, in which attributes, documents, but also a change history can be displayed. 3) Custom folder structures can be created based on metadata. 4) Easy sharing of information with internal and external partners. 5) Modification, review and approval can be done at a central location. 6) Information requirements (required documents and attributes) can be stored per object class (e.g. centrifugal pump).

Can general product information also be found on an IEP?

Yes, this is possible, provided that the manufacturer has created it and released it to the operator. Organizing general product information (manuals, certificates) on an IEP has the advantage that it does not have to be stored for each individual physical object, but can be organized centrally at model or product level.